Are you ready to unlock the secrets of OCA lamination machines? These incredible devices are revolutionizing the world of smartphone screen repair, and I’m pumped to share everything I’ve learned about how they work. Let’s dive in and explore the fascinating technology behind these game-changing machines!

What Is an OCA Lamination Machine?

OCA lamination machines are specialized tools designed to bond layers of a smartphone screen together using Optically Clear Adhesive (OCA). This process is crucial for repairing damaged screens and ensuring a crystal-clear display without any pesky air bubbles or imperfections.

- Further Reading: What is OCA Lamination Machine? A Guide for Repair Shop Owners

The Working Principle of OCA Lamination Machines

The OCA laminating machine’s working principle is based on creating a perfect environment for bonding screen components. Here’s a breakdown of how these machines work their magic:

1. Vacuum Creation

The first step in the OCA lamination process is creating a vacuum environment. This is crucial for eliminating air bubbles and ensuring a flawless bond between screen layers.

2. Precise Alignment

OCA lamination machines utilize sophisticated mold systems to guarantee the accurate positioning of all screen layers, ensuring a flawless lamination process and delivering high-quality repair results.

3. Controlled Pressure Application

Once started, the OCA lamination machine applies precisely regulated pressure, evenly distributed across the screen using parallel guides. This ensures no distortions or imperfections, keeping the process safe and efficient.

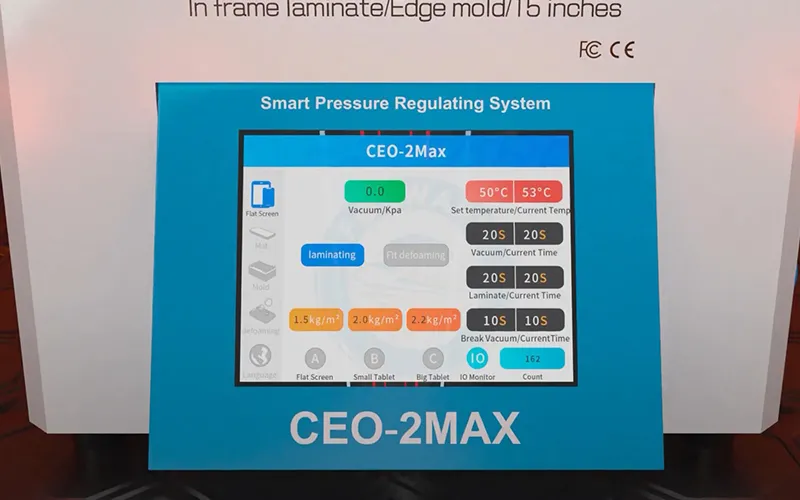

4. Temperature Regulation

Many OCA lamination machines incorporate heating elements to soften the OCA and improve adhesion. The temperature is carefully regulated to achieve optimal bonding without damaging sensitive components.

5. Automated Process Control

Modern OCA lamination machines are equipped with PLC (Programmable Logic Controller) systems that fully automate and fine-tune the lamination process. After lamination, they also automatically run the defoaming cycle, ensuring consistency and precision in every repair.

Key Components of OCA Lamination Machines

To truly understand how OCA lamination machines work, we need to look at their essential components:

- Vacuum Pump: Creates the necessary vacuum environment for bubble-free lamination.

- Alignment System: Ensures precise positioning of screen components.

- Pressure Application Mechanism: Applies even pressure for uniform bonding.

- Heating Elements: Regulates temperature for optimal OCA adhesion.

- PLC Control System: Automates and monitors the entire lamination process.

- Lamination Chamber: The enclosed space where the magic happens!

Benefits of Using OCA Lamination Machines

OCA lamination machines offer several advantages for screen repair:

- Bubble-Free Results: The vacuum environment ensures a perfect, bubble-free bond.

- Improved Clarity: OCA provides better optical clarity than traditional adhesives.

- Increased Durability: The strong bond created by OCA enhances screen durability.

- Consistency: Automated processes ensure consistent results across repairs.

- Cost-Effective: Enables high-quality repairs at a fraction of the cost of screen replacement.

Challenges and Considerations

While OCA lamination machines are incredibly useful, there are some challenges to consider:

- Initial Investment: Quality OCA lamination machines can be expensive.

- Training Required: Operators need proper training to use the machines effectively.

- Maintenance: Regular maintenance is necessary to keep the machines in top condition.

- Material Compatibility: Not all screen types are suitable for OCA lamination.

Conclusion

Understanding the workings of OCA lamination machines is essential for anyone in smartphone repair. These devices have revolutionized the industry, making screen repairs more efficient and cost-effective. Looking ahead, OCA lamination technology will remain crucial in maintaining the appearance and performance of our devices.

Whether you’re a repair expert or a tech enthusiast, this technology is worth paying attention to. So next time you encounter a cracked screen, remember the innovative process behind OCA lamination. OCADB continues to support this exciting journey into mobile device technology.